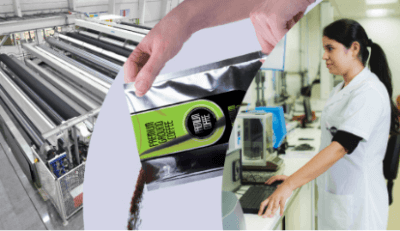

Terphane polyester films offer thin films, barrier, flexibility of shapes and sizes, printability and more sustainable processes and materials.

The technologies and processes applied in each development are of the latest generation. Terphane is also concerned with offering the best service, from the development of customized structures to the guarantee of their efficient processability in various applications.

We offer several structures, from the simplest to the most sophisticated, which can reach up to 4 layers. Each structure is designed to offer the best properties for flexible packaging.

The idea is not to develop a product, but a solution in line with market an customer needs.

Please feel free to contact our market representatives about the availability of Terphane solutions in your country.

BOPET film

BOPET is more commonly known as biaxially oriented polyester. The resin used to make this is a material that, when processed by extrusion, becomes a plastic film. This material stands out for a series of benefits and characteristics that make it ideal for the production of flexible plastic packaging.

Below are some benefits and characteristics of BOPET:

- Mechanical and Barrier Properties – BOPET is known for its excellent mechanical, optical, and barrier properties, thanks to the biaxial orientation process. This means it can better protect products from oxygen, grease, aromas, and water vapor. In the specific case of food, these properties are essential for extending shelf life and preventing waste. The properties can be defined according to the specific needs of the products to be packaged.

- Lightweight and Versatile – These films are extremely lightweight and versatile, facilitating transportation and storage, and reducing logistical costs overall. Additionally, its flexibility allows for the creation of packaging in various shapes and sizes, easily adapting to product needs. The material also ensures good printability, which highlights the product at the point of sale. It is also possible to use various decorative resources, such as matte effect or soft touch, in addition to features that make consumption more convenient, practical, and functional, for example, with the insertion of straws, dispensing spouts, and caps in the packaging (bags or stand-up pouches).

- Excellent Sealing Performance – Another important property of polyester is its sealing ability, making it an effective material for preserving food and other products that require a secure environment inside and outside the packaging.

- Sustainability – In recent years, the recycling of polyester (PET) has advanced significantly in Brazil and worldwide, allowing the material to be part of a circular production and consumption chain. It is 100% recyclable and can be used to produce new items after post-consumer recycling, including for food contact. This advancement is possible thanks to cutting-edge recycling technologies and is essential to minimize any environmental impact of the material, in addition to promoting its circularity.

Another aspect is that BOPET can be produced with additives that contribute to its degradation under controlled conditions, such as landfills.

BOPET (biaxially oriented polyester) offers a unique combination of durability, flexibility, and barrier properties, making it an excellent choice for flexible plastic packaging. Its characteristics enhance product preservation and offer opportunities to innovate in packaging design and production, contributing to more sustainable practices.

Across its many product lines, Terphane highlights:

Questions on how to optimize your business or packaging, please contact us.

Convenience

This attribute has never been more relevant for packaging. Consumers are asking for a functional and practical product, available for consumption on the go and that keeps the food inside intact.

The sealable Terphane polyester films offer convenience through easy opening, tamper-evident permanent sealing, resealing, anti-fogging, and high barrier. Transparent, white, metallized, or matte films present a series of characteristics that ensure the excellent performance of the packaging at the point of sale and the best consumer experience when using the product.

Please feel free to contact our market representatives about the availability of Terphane solutions in your country.

Understand the denomination for these films:

| Denomination | Description |

| C | Clear : very high transparency |

| AF | Anti-fog : anti-fog feature |

| H | Higher sealing strength |

| T | Corona treatment |

Get to know the products of these lines:

2. Lock Seal

(permanent sealing)

3. Resealable

Easy Open and Resealable Products

Click on the films to view the product characteristics

|

Product |

Sealing strength |

Sealing type |

Seals to: |

|

|

Easy open |

Easy Open (resealable) |

|||

| 10.63T | + | x |

Sealable/peelable for PET, PVC, PLA, PC, dual ovenable, self-venting film with Corona treatment on one side for printing. Suitable for tray lidding, cap liners and overwrap applications |

|

| 10.63TH* | ++ | x |

Same as 10.63T with higher sealing strength |

|

| 10.63HTAF | ++ | x |

Same as 10.63T with higher sealing strength, and anti-fog |

|

| 10.63CT | + | x |

Clear sealable/peelable for PET, PVC, PLA, PC, dual ovenable, self-venting film with Corona treatment on one side for printing. Suitable for tray lidding, and overwrap applications |

|

| 10.63CTAF* | + | x |

Same as 10.63CT with anti-fog |

|

| 10.63OT | ++ | x |

Sealable/peelable for PET, PVC, PLA, PC, dual ovenable, self-venting film. Suitable for tray lidding, cap liners and overwrap applications requiring higher seals than 10.63TH |

|

| 10.63HOT | +++ | x |

Sealable/peelable for PET, PVC, PLA, PC and aluminum smooth wall, dual ovenable, self-venting film. Suitable for tray lidding, cap liners, and overwrap applications requiring high seals than 10.63OT and pasteurization |

|

| 10.64T | + | x |

Sealable/peelable for PP, PE, PS with Corona treatment on the opposite side. Suitable for tray lidding, cap liners and overwrap applications |

|

| 10.64HT* | ++ | x |

Same as 10.64T with higher sealing strength |

|

| 10.64TAF | + | x |

Same as 10.64T with anti-fog |

|

| 10.64HTAF* | ++ | x |

Same as 10.64T with higher sealing strength, and anti-fog |

|

| 10.64HTW (White) | ++ | x |

White sealable/peelable for PP, PE, PS with Corona treatment on the opposite side. Suitable for tray lidding, cap liners and overwrap applications requiring higher seals than 10.64T |

|

| LIDBAR-e (High barrier) | ++ | x |

HIGH BARRIER sealable / peelable for PP, PE, PS, APET, CPET, modified CPET, PETG, rPET, PVC, PC, PLA, PET coated paperboard with anti-fog on one side with Corona treatment on the opposite side |

|

| RESEAL | ++ | x |

APET, rPET, and PET coated paperboard trays, bowls, tubs, and other containers |

Products with permanent sealing (lock seal)

Click on the films to view the product characteristics

|

Product |

Sealing strength |

Aspect |

Seals to: |

||

|

Transparent |

Matte |

Metalized |

|||

| 10.93T* | ++ | x |

Coextruded heat sealable PET designed for mono-layer and laminated overwrap, and tamper evident lidding applications. Seals to itself, APET, CPET, PET coated paperpoard, and PVC. Corona treated on one side for printing and laminating |

||

| 10.94T* | +++ | x |

Coextruded heat sealable PET designed for mono-layer and laminated overwrap, and tamper evident lidding applications. Seals to itself, APET, CPET, PET coated paperpoard and PVC. High SEAL strength with corona treatment on one side for |

||

| 10.95T | +++ | x |

Coextruded heat sealable PET designed for mono-layer and laminated overwrap and tamper evident lidding applications. Seals to itself, APET, CPET, PET coated paperpoard and PVC. High SEAL strength with corona treatment on one side for printing and lamination.Higher seal strenght than 10.94T |

||

| 10.96 | + | x |

Seals to itself |

||

| SMAT | ++ | x |

Seals to itself |

||

| 10.94TAF | +++ | x |

Same as 10.94T with anti-fog |

||

| 10.94AF | ++ | x |

Seals to itself, APET, mono CPET, APET/CPET, modified CPET, PETG, rPET, PVC, PC, PLA, PET coated paperboard trays or containers, bottles, and jars |

||

| MSEAL | ++ | x |

Seals to itself, APET, mono CPET, APET/CPET, modified CPET, PETG, rPET, PVC, PC, PLA, PET coated paperboard trays or containers, bottles, and jars |

Barrier

Ensuring that a product lasts and does not spoil easily, especially when it comes to food, is high-priority today. The world is trying to manage against food waste, so preservation is essential to make sure more people get the resources they need.

When it comes to barrier properties – be it oxygen, moisture, fat, aroma, etc. – polyester films excel in their performance. Terphane offers the most diverse grades, featuring specific barrier properties to meet every need and suitable for a wide range of products.

Please feel free to contact our market representatives about the availability of Terphane solutions in your country.

Barrier Metallized Films

Click on the films to view the product characteristics

|

Product |

Metal adhesion |

Barrier** |

Treatment on the opposite face of the metal |

Hot fill |

Isotropic |

sealing strength |

|

|

Oxygen |

Water vapor |

||||||

|

25°C - 85% UR |

38°C - 90% UR |

||||||

|

(cm³/m².day) |

(g/m².day) |

||||||

| M2BR | ++ | 0.5 | 0.5 | Corona | x | ||

| MA | ++ | 1.0 | 1.0 | Plain | |||

| MAR | ++ | 1.0 | 1.0 | Corona | |||

| MAX | ++ | 1.0 | 1.0 | COEX | |||

| MAXLID | ++ | 1.0 | 1.0 | COEX | x | ||

| MARLID | ++ | 1.0 | 1.0 | Corona | x | ||

| MH* | ++ | 1.5 | 1.5 | Plain | x | ||

| MP | + | 1.0 | 1.0 | Plain | |||

| MQ | + | 1.0 | 1.0 | Chemical | |||

| MX* | + | 1.0 | 1.0 | COEX | |||

| MZ | + | 1.0 | 1.0 | Chemical | |||

| MZ2 | + | 1.0 | 1.0 | Chemical | |||

| MZAR | ++ | 1.0 | 1.0 | Corona | x | ||

| SHX | +++ | 1.0 | 1.0 | COEX | |||

| MSEAL | + | 1.0 | 1.0 | Sealable | x | ++ |

Modified Surface

Terphane’s modified surface line meets the modern consumer’s demand for matte packaging. Holding a high rank at points of sale (POS), matte textures tend to attract consumers, causing them to interact more with the products. For brand owners, this is a way to differentiate their products at the POS and ensure greater competitiveness.

The modified surface line of films also includes products with a modified coefficient of friction (COF) in comparison to standard products. Products with high COF prevent pouches from slipping over the others when stacking. On the other hand, those products with low COF allow smoother sliding in lines with high packaging speed.

Please feel free to contact our market representatives about the availability of Terphane solutions in your country.

Modified Surface

Click on the films to view the product characteristics

|

Product |

White |

Matte |

High COF |

Treatment on the opposite face |

| 61.20 | x | Plain | ||

| 68.15 | x | Corona/COEX | ||

| 68.25 | x | Corona/COEX | ||

| CMAT | x | COEX | ||

| SMAT (sealable) | x | Corona | ||

| VMAT2Z (Velvety touch) | Soft Mate | Chemical | ||

| rVMAT (Soft matte)* | Soft Mate | Plain | ||

| 10.91 | x | COEX | ||

| 10.49 (UV barrier) | x | COEX |

Regular films and specialties

The same packaging is not always suitable for several products. Some standard packaging can be produced with line films, but other projects demand customized packaging.

Terphane’s innovative New Product Development Team works tirelessly to meet – and, if possible, anticipate – these market needs. Through technologies and the dedication of highly trained professionals, it is possible to develop specific polyester films for special applications.

Please feel free to contact our market representatives about the availability of Terphane solutions in your country.

Regular and Specialties

Click on the films to view the product characteristics

|

Product |

Surface Treatments |

Specialty |

| 10.10 | Plain | |

| 10.15 | Corona | |

| 10.21* | Plain / COEX | |

| 10.71 | Plain / Chemical | |

| 10.41 | Chemical / COEX | Bi-treated |

| 10.55 | Corona / Chemical | Bi-treated |

| 10.72 | Chemical / COEX | Bi-treated |

| 10.75 | Corona / Chemical | Hot fill |

| 10.81 | Low COF / COEX | COF differentiated |

| 10.91 | High COF / COEX | COF differentiated |

| 10.61 | COEX | Isotropic |

| LID | Chemical / COEX | Isotropic |

| RT | COEX | Retort |

| 10.48 | COEX | UV Barrier |

| 10.49 | High COF UV / COEX | UV barrier |

Sustainable

The Ecophane line meets the growing demand in the global market for films that guarantee recyclable packaging production with recycled content. Polyester is the only resin that, after being recycled, can be used in the production of new packaging, including packaging for food contact.

In addition to ensuring a lower use of virgin raw materials, the new Ecophane rPET films containing PET PCR resin support the circular economy concept: disposable PET packaging or other items are collected, recycled, and become packaging again.

ECOPHANE bPET – as biodegradable, accelerates the decomposition of the material by up to 95% in landfill conditions, transforming “plastic” into a natural fertilizer.

Ecophane

Click on the films to view the product characteristics

|

Product |

Ecophane |

Surface treatment |

|

|

PCR |

Biodegradable |

||

|

rPET |

bPET |

||

| 10.21 | r10.21 | b10.21 | COEX / Plain |

| 10.25 | b10.25 | COEX / Corona | |

| 10.63CTAF | r10.63CTAF | Easy open AF / Corona | |

| 10.63TH | r10.63TH | Easy open / Corona | |

| 10.64HT | r10.64HT | Easy open / Corona | |

| 10.64HTAF | r10.64HTAF | Easy open AF / Corona | |

| 10.93T | r10.93T | Lock Seal / Corona | |

| 10.94T | r10.94T | Lock Seal / Corona | |

| 15.87L | r15.87L | Plain / Corona | |

| 22.00 | r22.00 | PVdc / Plain | |

| MH | rMH | bMH | Metal / Plain |

| MX | rMX | bMX | Metal / COEX |

| SHX | rSHX | Metal / COEX |

Questions on how to optimize your business or packaging, please contact us.

Services

Terphane utilizes innovative and disruptive technologies that ensure the efficient and sustainable production of biaxially-oriented polyethylene terephthalate (BOPET) films. These films are manufactured via a vertical chain from resin creation to special film coatings. Terphane’s films are unique and meet the most diverse market demands, including tailormade projects for specific applications.

Service Portfolio

Customized solutions to meet market demands

Counting on a team of specialists who is always ready to listen to the market’s needs – and if possible, anticipate them – Terphane implements a variety of technological resources to develop films that add value to the product and the brand, assuring the sustainable growth of the business of its direct and indirect customers.

All developments are screened by a state-of-the-art test laboratory, and deliveries are equally efficient and fast, thanks to an exclusive reverse logistics system that leverages returnable plastic packaging. Full market satisfaction and total engagement with all links in the value chain are the driving force enabling Terphane to deliver innovative and competitive solutions that create value for all.

Questions on how to optimize your business or packaging, please contact us.